About the product of vegetable powder

* About the material area

Nestled on the high hills and mountains, farming has been associated with many generations of people in the land of Yen Thang, Yen Mo district. With more than 3,000 hectares of agricultural land, if in the past, farmers only knew about plowing rice and growing vegetables of all kinds, but also depended a lot on the weather situation that the season was not guaranteed, sometimes it was okay or not. Now, after boldly introducing the model of planting vegetables to replace inefficient areas of vegetable crops, initially showing high economic efficiency, promising this is a crop that brings a good source of income to local people.

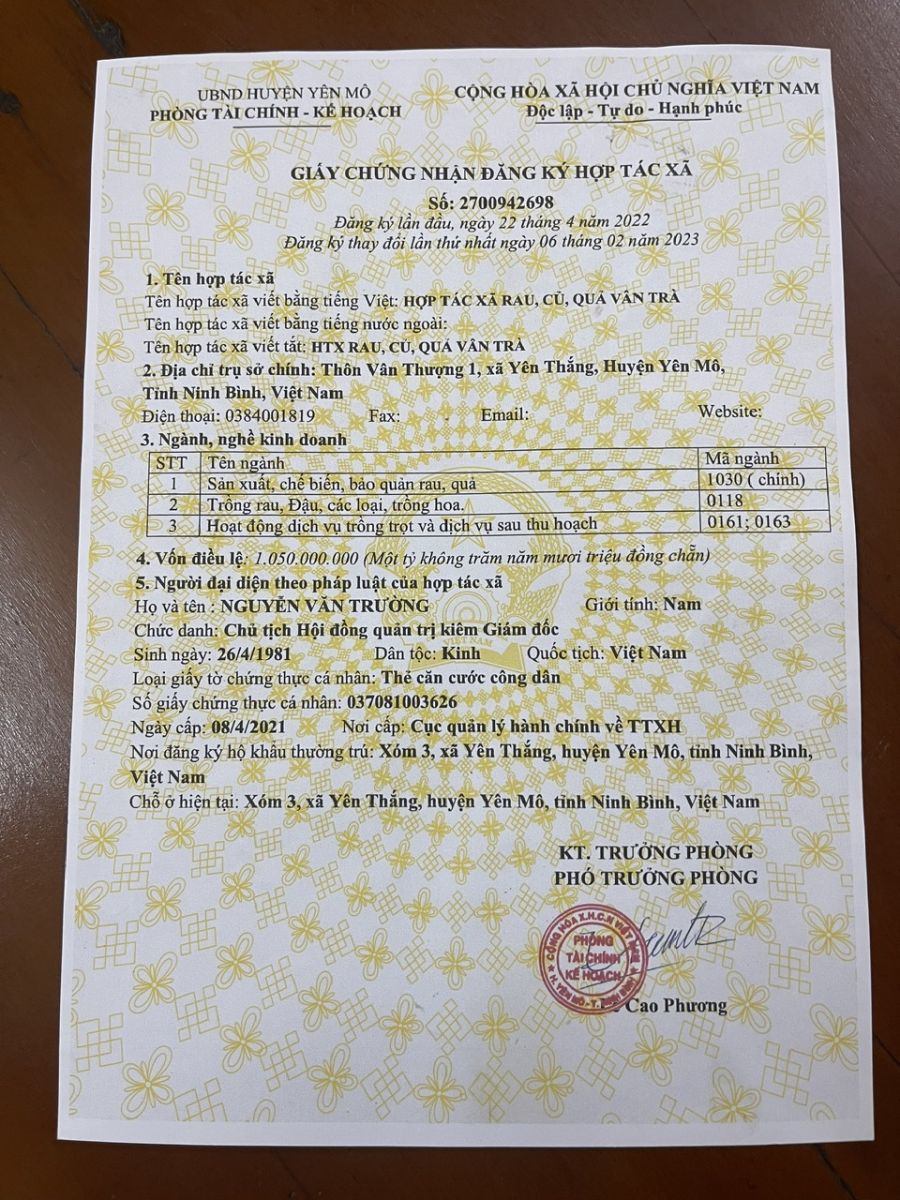

Currently, Van Tra Vegetable, Tuber and Fruit Cooperative has 9 teams with 1,305 regular production households. The cooperative is maintaining about 8 hectares of vegetables all year round, harvesting about 200 tons of fresh vegetables a year. The cooperative still maintains a part of the land fund to grow traditional food crops, the rest of the production households participating in the cooperative gradually switch to growing greens to ensure the supply chain for the production of vegetable powder products.

Initially, it was only a few small farmers since 2017, after a few years until now, spinach has become a staple crop, bringing high economic value to cooperative members. The entire planting process strictly follows the rules of food safety and hygiene, applies the process of using pesticides, is proactive in composting organic fertilizer, applying soil improvement after each harvest, helping to both increase nutrition and create looseness for the soil. In 2021, the vegetable tree of the cooperative was certified as safe by the Sub-Department of Cultivation and Plant Protection of Ninh Binh province.

With the advantage of growing fresh spinach all year round, in addition to the support of the application of high technologies in processing, preservation and production, the vegetable powder products of Van Tra Vegetable, tubers and fruit cooperative are considered to have great potential to compete with vegetable powder products of unknown origin floating on the market.

Van Tra Vegetable, tubers and fruits cooperative applies Science and technology to produce fresh vegetables

* About Machinery, equipment

- 200kg MSL2000 Mactech refrigerated dryer: is a large dryer line with 32 drying trays. The machine has the ability to dry up to 200kg and can dry many different types of products to help keep beautiful colors, keep high nutritional content in the product. The 200kg MSL2000 Mactech cold dryer has a drying temperature of about 15 - 60 degrees Celsius, making it versatile for most agricultural products.

- Yorda Stonemills ultra-fine grinder: There is a mill made from granite, a stone with a large volume of heat absorption, does not generate more heat during the grinding process, ensuring that the finished powder retains the nutritional value content found in nature.

- Automatic powder bag packing machine (DXD-350F)

Photo: Put raw materials into the 200kg MSL2000 Mactec cold dryer performs a 24-hour drying process

* About product production process

Van Tra Vegetable, Tubers and Fruit Cooperative has applied the most modern techniques in fully maintaining the freshness of the product, after the fresh spinach is washed, it will be put into cold drying for 24 hours, the optimal humidity in the cold dryer will help the bok choy retain its medicinal properties, along with the combination of bactericidal UV lamp will help the product after processing be preserved longer. Next, the spinach will be ground with a granite mortar for another 12 hours to keep the original taste and color. All processes from production to packaging are closed and ensure food hygiene and safety. According to calculations, to make 1kg of vegetable powder products, it takes about 10kg of raw materials, with a selling price of about 1.5 million VND/kg.

.png)